How to Extend the Life of Your Hydraulic Cylinders:

A Comprehensive Guide

Hydraulic cylinders are a critical component of many industrial machines, and maintaining them is key to ensuring smooth operations and reducing costly downtime. In this guide, we’ll walk you through essential maintenance tips, common issues to watch out for, and expert advice on how to extend the lifespan of your hydraulic cylinders.

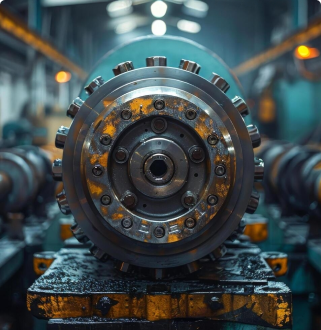

1. Understand the Role of Hydraulic Cylinders in Your Machinery

Hydraulic cylinders are responsible for providing the force that powers many types of industrial equipment, from construction vehicles to manufacturing machinery. They convert hydraulic energy into mechanical energy, enabling your machinery to perform essential functions such as lifting, pushing, pulling, or rotating. Because of their central role, even minor malfunctions can have a big impact on your operations.

2. Common Causes of Hydraulic Cylinder Wear and Tear

Hydraulic cylinders are built to handle heavy loads and constant movement, but over time, wear and tear are inevitable. Here are some of the most common issues that can reduce the lifespan of your hydraulic cylinders:

Fluid Contamination: Dirt, debris, or metal particles in the hydraulic fluid can cause abrasions on the cylinder’s internal components, leading to premature wear.

Seal Failure: Worn or damaged seals can lead to fluid leaks, reducing the efficiency of your cylinder and causing internal damage.

Overloading: Operating the cylinder beyond its design limits can cause excessive stress, leading to cracks or structural damage.

Corrosion: Exposure to moisture or harsh environments can lead to rust and corrosion, weakening the cylinder’s metal components.

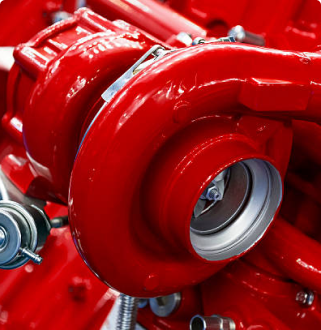

3. The Importance of Choosing Quality Parts and Components

When it comes to hydraulic cylinder repairs and maintenance, using high-quality parts is crucial. Cheap or low-quality seals, rods, and other components may save you money upfront, but they will wear out faster and lead to more frequent repairs. Invest in durable, well-made parts that will extend the life of your cylinder and reduce overall maintenance costs.

At Prime Hydraulic Logistics, we manufacture custom cylinder components that are built to last, ensuring your hydraulic systems operate efficiently for longer periods.

4. Work with Experts for Long-Term Cylinder Health

While regular maintenance can go a long way in extending the life of your hydraulic cylinders, sometimes you need the help of professionals. Whether it’s for advanced repairs, complete rebuilds, or expert diagnostics, partnering with a reliable service provider like Prime Hydraulic Logistics ensures that your hydraulic systems receive the highest level of care.

Conclusion

Maintaining and extending the life of your hydraulic cylinders doesn’t have to be complicated. By following routine maintenance practices, using high-quality components, and addressing issues early, you can significantly improve the longevity and performance of your cylinders. For more complex issues, it’s always best to consult with professionals who have the expertise to keep your equipment running smoothly.

Need help with hydraulic cylinder repairs or component manufacturing? Contact Prime Hydraulic Logistics today and let our team of experts provide the solutions you need.

Stay Updated with Our Newsletter

Be the first to know about our latest hydraulic repair solutions, new product launches, and special promotions. Subscribe to our newsletter and receive

Sign Up for Exclusive Insights & Offers

- Expert tips on maintaining your hydraulic systems

- Updates on industry trends and innovations

- Exclusive discounts and offers only available to subscribers

Hydraulic Insights & Tips

Explore our latest articles and stay informed about the best practices for maintaining and upgrading your hydraulic systems.