Industries We Serve

At Prime Hydraulic Logistics, we pride ourselves on offering top-quality hydraulic solutions to a wide range of industries. Our experience, technical expertise, and commitment to excellence ensure that our clients receive the best service, regardless of the sector they operate in. We understand the unique challenges of each industry and provide tailored solutions to keep your equipment running efficiently.

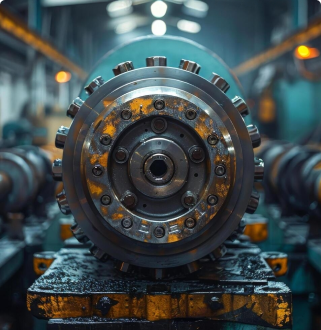

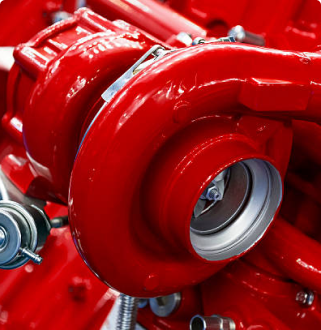

Hydraulics for every industry

At Prime Hydraulic Logistics, we provide comprehensive hydraulic repair services, cylinder component manufacturing, and premium turbocharger sales for trucks. Our team of experts is committed to delivering high-quality solutions that keep your machinery and vehicles running at peak performance.

Land Rigs

Hydraulic systems are vital for the smooth operation of land rigs, providing the force required for drilling, lifting, and controlling rig equipment. At Prime Hydraulic Logistics, we offer tailored hydraulic repair services to meet the high demands of the drilling industry. Whether it’s repairing hydraulic cylinders, pumps, or manufacturing custom components, we ensure your rig is operating at peak efficiency with minimal downtime, even in the harshest environments.

Recycling Industry

The recycling industry relies heavily on hydraulic-powered machinery to compress, crush, and compact waste materials. These machines endure extreme conditions, making reliable hydraulic systems essential for continuous operation. Our expert team provides maintenance, repairs, and component manufacturing to keep recycling equipment such as balers and compactors running efficiently, reducing downtime and improving operational productivity.

Rental Equipment

Rental equipment companies need their machinery to be in top working condition to meet customer demands. We specialize in maintaining and repairing the hydraulic systems in rental equipment, including excavators, loaders, and cranes. Our quick turnaround times and reliable service ensure that your rental fleet is always ready to perform, minimizing disruptions and maximizing profitability.

Offshore & Marine

In the offshore and marine sectors, hydraulic systems face harsh environments with constant exposure to saltwater and extreme weather conditions. From ship cranes to winches and drilling equipment, we offer specialized hydraulic repairs and preventive maintenance to ensure your equipment performs reliably under pressure. Our custom component manufacturing also ensures that your hydraulic systems meet the demands of offshore operations.

Chemical Industry

Hydraulic systems in the chemical industry must meet strict safety standards and perform under highly controlled conditions. We provide specialized repair and maintenance services for hydraulic equipment used in chemical processing plants, ensuring the safe and reliable handling of chemicals. Whether it’s hydraulic pumps, valves, or cylinders, we ensure that your systems run smoothly while adhering to stringent safety protocols.

Dredging

Dredging operations rely on hydraulic power to manage heavy equipment like dredgers, excavators, and cranes, which often operate in extreme environments. We provide customized hydraulic repair and maintenance services that keep your dredging equipment operating efficiently, minimizing downtime and maximizing operational output. Our team ensures that your hydraulic systems are reliable, durable, and ready for any challenge.

Lumber

The lumber industry depends on hydraulics to operate sawmills, loaders, and forestry machinery. With heavy loads and constant motion, these systems require regular maintenance to ensure optimal performance. We offer hydraulic repair and custom component manufacturing tailored to the lumber industry, ensuring that your equipment operates efficiently and can handle the rugged demands of logging and milling operations.

Cranes

The recycling industry relies heavily on hydraulic-powered machinery to compress, crush, and compact waste materials. These machines endure extreme conditions, making reliable hydraulic systems essential for continuous operation. Our expert team provides maintenance, repairs, and component manufacturing to keep recycling equipment such as balers and compactors running efficiently, reducing downtime and improving operational productivity.

Steel Mills

In steel mills, hydraulic systems must withstand extreme pressures, high temperatures, and continuous operation. We specialize in maintaining and repairing hydraulic machinery used in steel production, such as presses and conveyor systems. Our hydraulic services ensure that your equipment remains reliable and efficient, even in the most demanding environments, minimizing costly downtime and maximizing production output.

Construction

From bulldozers to excavators, hydraulic systems are at the core of construction machinery. Prime Hydraulic Logistics provides expert repairs and maintenance for hydraulic equipment used in construction, ensuring that your machinery operates smoothly and efficiently. Our custom component manufacturing services also ensure that your equipment meets the specific needs of construction projects, improving reliability and performance in the field.

Agriculture

In the agriculture industry, hydraulic systems are critical for the operation of tractors, harvesters, and other farm equipment. We provide maintenance, repair, and component manufacturing services to keep your agricultural machinery running efficiently throughout planting, growing, and harvest seasons. Our solutions are designed to improve equipment longevity, reduce downtime, and enhance productivity in agricultural operations.

Waste Refuse

Waste refuse and management operations rely on hydraulics to power compactors, loaders, and sorting machines. At Prime Hydraulic Logistics, we offer hydraulic repair services that keep waste handling equipment operating efficiently, even in the toughest conditions. From preventive maintenance to custom component manufacturing, we help ensure that your hydraulic systems can handle high workloads with minimal disruption.

Stay Updated with Our Newsletter

Be the first to know about our latest hydraulic repair solutions, new product launches, and special promotions. Subscribe to our newsletter and receive

Sign Up for Exclusive Insights & Offers

- Expert tips on maintaining your hydraulic systems

- Updates on industry trends and innovations

- Exclusive discounts and offers only available to subscribers

Hydraulic Insights & Tips

Explore our latest articles and stay informed about the best practices for maintaining and upgrading your hydraulic systems.